|

Send this page to a friend! Fill in the form bellow | ||

news

Ford: greener cars using renewable and recyclable materials

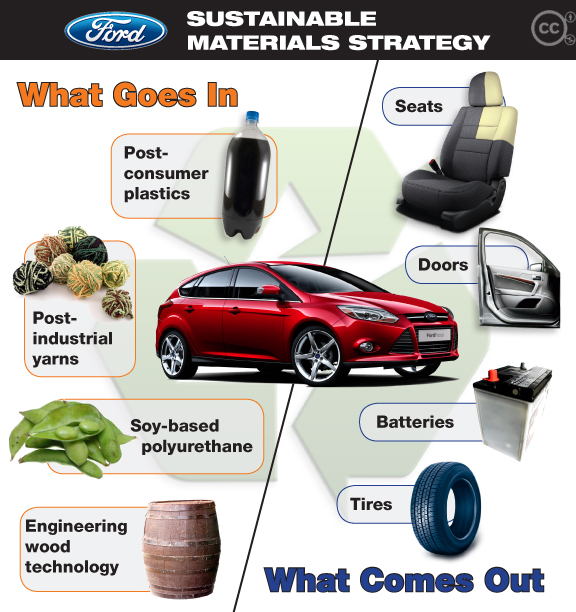

Ford has been increasing the use of renewable and recyclable materials in its vehicles so that they become more eco-firendly. For example on the 2010 Ford Taurus the brand used soy and bio-based seat cushions and seatbacks. According to Ford their models are actually 85 percent recyclable by weight.

In the year 2009 4.5 million dollars have been saved by Ford thanks to the use of recycled materials. Between 25 and 30 million pounds of plastic was deflected from landfills in North America, also thanks to this action.

“By increasing the use of recycled or renewable content and reducing the use of undesirable materials whenever possible, we’re helping to reduce waste to landfills by millions of pounds – and we’re doing it around the world,” said John Viera, Ford’s director of Sustainability and Environmental Policy. “More than ever before, the spirit of ONE Ford that drives our global product strategy also drives our commitment to sustainability.”

Currently there are eleven models that are using the bio-based seat cushions and seatbacks including: the 2010 Ford Taurus, Ford Mustang, F-150, Focus, Flex, Escape, Expedition, Econoline, Mercury Mariner, Lincoln MKS and Navigator.

This makes part of Ford’s efforts to reduce its environmental footprint, a strategy that is completed with the investigation and development of advanced fuel-efficient vehicle technologies.

At Ford material engineers have been researching new possible uses of sustainable materials, while also working on those already known to achieve the same quality of common usage materials.

According to Valentina Cerato, Ford materials engineer in Europe “Sustainable materials need to meet the same high standards for quality, durability and performance as virgin material; there can be no compromise on product quality.”

For example, researchers are developing natural-fiber composites as a potential substitute for the glass fibers traditionally used in plastic car parts. This will make these parts stronger but also reduce the vehicle weight.

Ford researchers are also trying to discover ways to use resources such as corn, sugar beets, sweet potatoes and other vegetables to produce plastic in order to reduce the dependency on petroleum and the CO2 emissions, and allow the composting of the material at the end of a vehicle’s life.

Encyclopedia |

Contribute

more about Ford

latest news