|

Send this page to a friend! Fill in the form bellow | ||

news

Infiniti Releases Two More Parts of Its Look Inside Red Bull Racing

The new videos focus on composites and manufacturing

Infiniti InfinitiJapan, 1989 > present31 models

InfinitiJapan, 1989 > present31 models

993 photos

5 videos

has been using its access inside Red Bull Red BullAustria, 2004 > present12 models

Red BullAustria, 2004 > present12 models

1049 photos

3 videos

to make a four-part series of short documentaries about how the team creates new cars. The first part focused on design and quick prototyping new parts. The latest parts look at the role composites play and manufacturing parts.

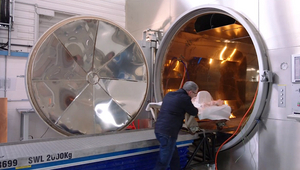

Part 2 looks at the role carbon fiber plays in Formula 1. The first carbon fiber F1 chassis was made in 1981 and in over 30 years, the teams have found ways to use carbon fiber to make it stronger and lighter. To keep their designs secret, F1 teams do everything in-house, including making all of the molds for the parts. The teams also have autoclaves where the carbon fiber is baked under pressure to harden it.

The third part looks at the small portion of the car that is not carbon fiber, specifically the in-house, milled mechanical parts. Most of the parts start as a sold piece of material that is milled in a machine into shape.

Encyclopedia |

Contribute

more about Red Bull

latest news