|

Send this page to a friend! Fill in the form bellow | ||

news

The Carbon Fibre Revolution

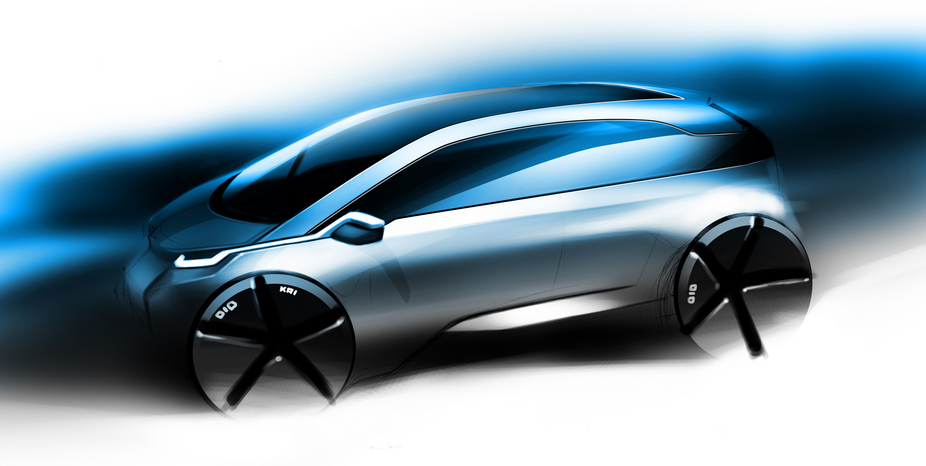

With its Megacity Vehicle (MCV), available to customers by 2013, BMW is attempting a revolution in automotive production. Not only will the car be one of the first electric cars developed from scratch as such and not as an electric variation of existing models. Also will it be the world’s first volume-produced vehicle with a passenger cell made from carbon fibre. The Megacity will be built as two modules: an aluminium chassis containing the electric drive-system and battery, and a body made almost entirely of carbon fibre will be fitted onto it.

Carbon-fibre technology has hitherto been reserved to fulfil high-performance demands in racing and airplane construction. This is due to its costliness. However, it is a very attractive option for the automotive industry for two reasons: light weight and extreme strength.

Carbon fibre is 30% lighter than aluminium and 50% lighter than steel. Such a lightweight carbon body will serve to offset the 250-350 extra kilograms typically brought about by electric vehicles and hence will extend their driving range.

Further, passenger security will be greatly enhanced as the carbon fibre bodies outclass the aluminium ones in crash-tests. The fibres are extremely tear-resistant. When woven into a lattice structure and impregnated with resin they can produce a part that is stronger than steel. Furthermore, damaged parts are easily repairable, which in addition to the fact that carbon fibre cars will not corrode, promises vehicles with as yet unknown longevity.

One might wonder why the miracle-material has not yet found its way into mainstream car-production, the major obstacle being its time and labour intense production process. BMW however, attempts to challenge these issues by introducing innovative production processes and making use of robots.

Another headache to the industry will be the recycling of the carbon-fibre cars at the end of their life-cycle. BMW is once again taking the lead and has developed a system to turn the used parts back into raw material. On the basis of the recycled parts, materials with 50% of the strength of newly produced carbon fibre can be manufactured.

And last but not least, car-makers will certainly have some creeping feelings over producing cars which supersede any further automotive purchases for their customers.

Contribute

latest news