|

Send this page to a friend! Fill in the form bellow | ||

news

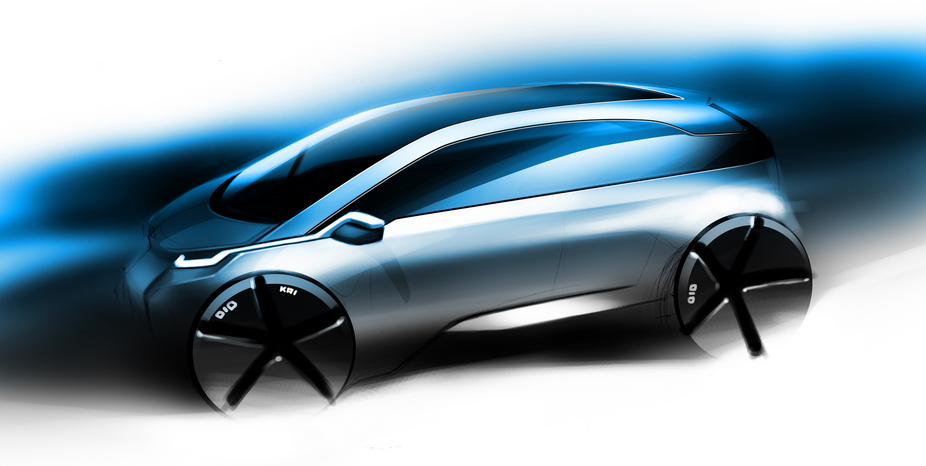

BMW expands Leipzig plant to produce Megacity Vehicle

Today BMW is announcing the expansion of its Leipzig plant, which will become Germany’s first location equipped to receive large-scale production of zero-emission electric cars. Until 2013 BMW will invest €400 million to construct new buildings and buy machinery for the production of the Megacity Vehicle (MCV). Thanks to the investment BMW will be creating almost 800 jobs.

The announcement ceremony counted with the presence of German Chancellor Dr Angela Merkel and Dr Norbert Reithofer, Chairman of the Board of Management of BMW AG, together with the Prime Minister of the German state of Saxony, Stanislaw Tillich, and the Governor of Washington state in the US, Chris Gregoire.

“By producing the Megacity Vehicle we are revolutionizing automotive design and production, and offering our customers the first purpose-built electric vehicle for urban areas. This will be the world’s first volume-produced car with a passenger compartment made from lightweight CFRP, as less weight enables a longer range,” explained Reithofer. “We made a conscious decision to produce the car in Germany, at our plant in Leipzig – our newest and most cutting-edge facility with the most flexible structures,” he added.

Including production of components, the BMW Group and the joint venture set up with the SGL Group for the manufacture of carbon fibres, the expansion will represent a total investment of €530 million in the project. The plants in Leipzig and Landshut and the joint venture facilities in Wackersdorf and Moses Lake (Washington state, USA), will be its beneficiaries. A total of over 1,000 jobs will be created as a result of the investment. The BMW plant in Dingolfing will produce important components for the drive system and chassis of the MCV.

In this new phase the BMW Group is investing on sustainability throughout the value chain for the Megacity Vehicle. This starts with the emission-free operation of the vehicle itself but is expanded to the whole production. In fact, BMW Group has set to itself ambitious goals in terms of environmental protection and the preservation of natural resources along the production process. For example, the company’s target is to bring its energy requirement down by 50 per cent and reduce water usage by 70 per cent per vehicle. The company is aiming to ensure that 100 per cent of the energy it uses comes from renewable sources.

BMW also announced that the BMW ActiveE – based on the BMW 1 Series Coupé – will go into production in 2011. The model represents the second step towards putting an emission-free electric vehicle into series production, after the MINI E. All the knowledge that has been received from the testing with the MINI E and BMW ActiveE is being channelled directly into the series development of the MCV.

From 2011 Leipzig will become BMW Group’s centre of expertise for the production of electric cars. To do so, BMW will also increase the number of apprenticeship places in Leipzig from 40 to 55 per year.

Encyclopedia | Engine -- Displacement -- Top Speed 90 mph Transmission -- Maximum power -- Type -- Fuel -- Fuel consumption (combined) -- | price -- annual ownership cost -- |

Contribute

more about BMW

latest news